PP

Polypropylene is a semi-rigid, tough and crystalline thermoplastic produced from propene (propylene) monomer. PP polymer is translucent, good chemical resistance, good fatigue resistance, integral hinge property, good heat resistance and durable.

Product Data Sheet:

Applications:

It is used in manufacturing utensils, housewares, toys, cars, plastic pallets, sportswear, lab, medical equipment, packaging for consumer products, plastic parts for various industries including the automotive industry, special devices like hinges and textiles.

Types

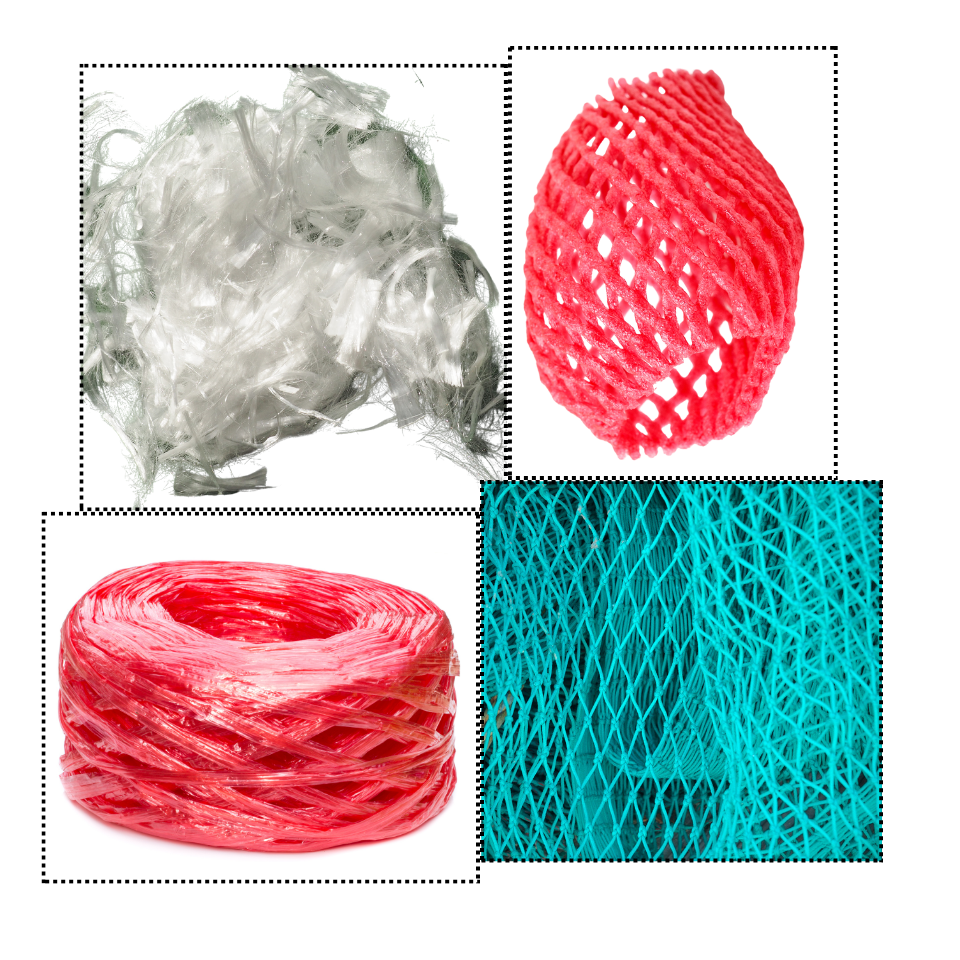

Raffia

PP Raffia is valued for its strength, lightweight nature, and versatility, making it a popular choice in a range of industries and applications.

These fibers are commonly used in the production of raffia products, which include woven bags, sacks, and other items. Some uses and applications of PP raffia are in packaging, agriculture, construction, fishing and geotextiles industry.

Injection Molding

PP (Polypropylene) injection molding is a manufacturing process commonly used to produce a wide range of plastic products using polypropylene as the base material. It is a versatile and cost-effective method for producing a wide variety of plastic products.

Common applications of PP Injection molding technique are in manufacturing of caps & closures, containers & packaging, automotive parts, household goods, medical devices, toys & consumer goods, electronics components, furniture parts.

Fiber

Polypropylene fibers are valued for their lightweight nature, resistance to moisture, and versatility in various applications. The specific characteristics of PP fibers make them suitable for diverse industries, ranging from construction to textiles and beyond.

These fibers have a variety of applications due to their unique combination of properties. Some common uses of polypropylene fibers are Geotextiles, Concrete Reinforcement, Carpeting and Rugs, Apparel and Textiles, Rope and Twine.

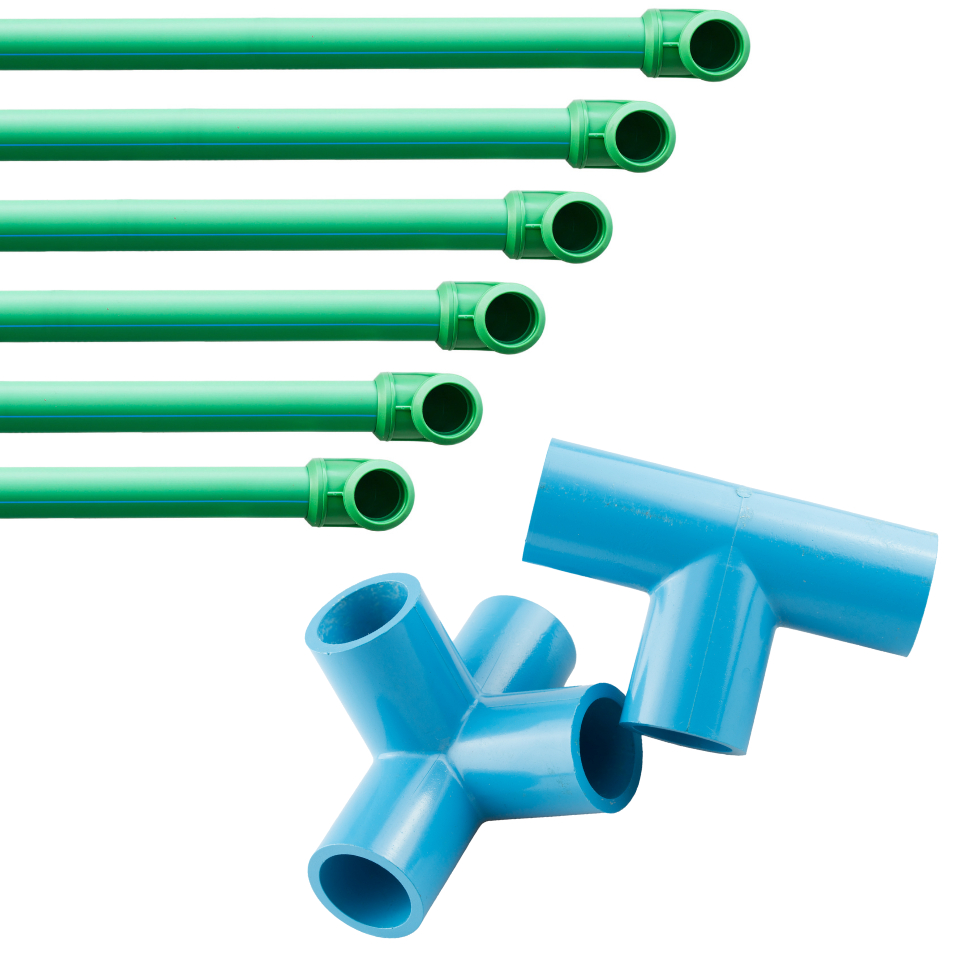

PP-R

PP random copolymer offers improved clarity, flexibility, and impact resistance compared to homopolymer PP. It is often chosen for applications where these properties are critical.

Some common applications are food containers, thin-wall packaging, housewares, and components requiring a combination of clarity and toughness.

PP-H

PP homopolymer is the most widely used type for injection molding applications. It offers a good balance of properties, including high stiffness, impact strength, and chemical resistance.

PP-H is employed in the production of parts and products such as caps and closures, containers, automotive components, housewares, and various consumer goods.